The one-piece molding of the new generation platform would be shelved by Tesla. The company is probably caught up by the technical difficulties of an overly ambitious project.

The €25,000 Model 2 would not be the only project abandoned by Tesla in recent months. It's a new time Reuters which reveals the information, this May 2, 2024. The American manufacturer would have lowered its ambitions to create its future models using gigacasting in a single part. What does this mean more concretely?

Advertisement

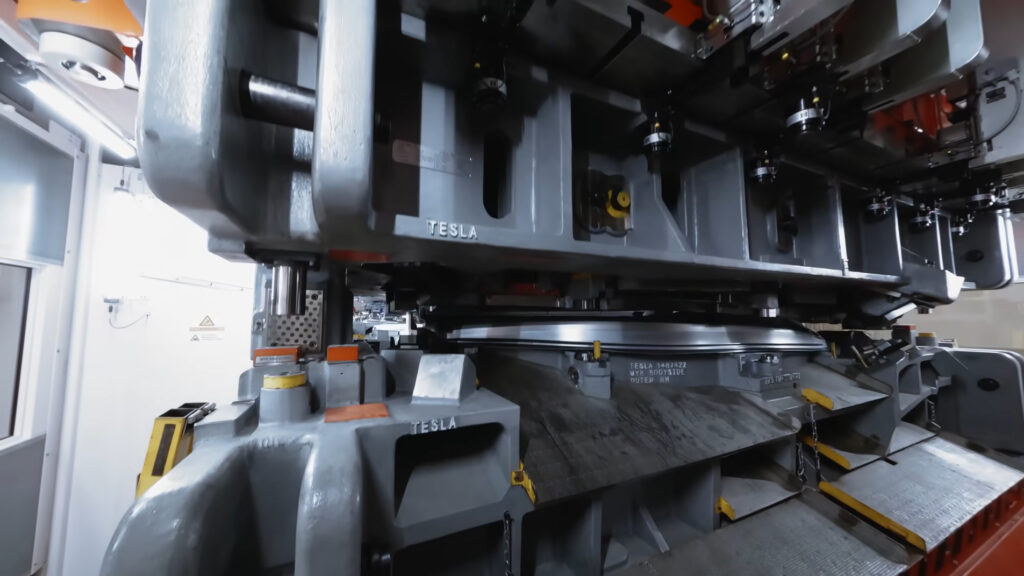

Tesla was the first manufacturer to reduce the number of parts welded together. The brand manufactures large sets using the gigacasting method, which has allowed it to lower production costs. Tesla's future platform was supposed to go even further in the size of single-piece molded parts, but everything does not seem to be going as planned.

Tesla's next-generation platform is in trouble

The next-gen platform – announced by Tesla in 2023 – was expected to bring two major innovations:

The two innovations combined should allow Tesla to simplify manufacturing, produce each vehicle more quickly, reduce the surface area of factories and thus reduce production costs by 50%. Without the gigacasting part, it is difficult to imagine that the savings achieved would be as strong as expected.

This is one of the reasons which could justify the suspension of the Model 2 project, even if Elon Musk still denies the information broadcast by Reuters on this subject. This would make sense, if the new platform does not achieve the set cost reduction objectives. This would also explain why the factory project in Mexico, which was to contribute to this, is also put on hold.

Advertisement

Return to a proven method

Sources close to the matter told Reuters that Tesla would have given up on this revolutionary process at the end of 2023. It is true that Elon Musk no longer addressed the subject during his speeches in 2024.

Tesla will continue to produce large sets using giant stamping presses, but the brand would return to a more classic 3-piece process: two pieces for the front and rear of the models and a central cradle for house the batteries. A method that is already used on the Tesla Model Y and the Cybertruck.

Too expensive and complicated development?

Casting ever larger parts is a challenge. The presses currently used by Tesla are already custom-made. Each gigapress and each mold represents a significant initial investment, to be profitable thanks to high production volumes. The larger the parts to be molded in a block, the more technical the mold and the pressure of the machine must follow, and this necessarily has an increasingly significant cost.

Other manufacturers, notably Chinese, have followed in Tesla's footsteps by adopting this manufacturing process for vehicle structural parts. However, the subject is still debated, especially because of the high rate of defective parts and the lack of repairability of the structure in the event of an impact. Many historic manufacturers therefore prefer to maintain more traditional assemblies, with several hundred parts to be assembled on the production line.

Gigacasting at Tesla is not just a question of optimizing production costs. It is also one of Elon Musk's many obsessions, who would like the cars of the future to resemble certain miniatures: a part for the underbody, onto which a part for the upper part of the vehicle would be grafted. Except that the reality is much more complex to achieve.

To obtain gigacasting in a single piece, imagined by Elon Musk, it would take a long development time. In the current environment, Tesla does not have this luxury. He must multiply new products to obtain the expected volumes. But then, if revolutionary gigacasting is no longer on the agenda, how will the robotaxi stand out from other models? The answer will probably be discovered on August 8.