With its view of Lake Geneva and the snow-capped mountains, Logitech's headquarters in Lausanne may have one of the most beautiful locations in the world. Located a few meters from EPFL (the Federal Polytechnic School of Lausanne), it is also perfectly positioned to recruit young engineers seeking recognition at a tech giant. Because yes, despite appearances, Logitech is a tech giant.

Since 1981, Logitech has been manufacturing computer accessories. The Swiss giant, also established in the United States and Asia, is not afraid to compare itself to GAFAM on certain aspects. It must be said that he has always supported them, without ever having tried to compete with them, since he wants to be “neutral and passionate”.

Advertisement

Between 1 to 4 years per project, with numerous testing phases

“Design is not just about appearance”explains Tanyel, one of the leaders of the team of the same name at Logitech. “The literal translation is rather design”.

At Logitech, a new mouse is designed like a new iPhone at Apple. The company's engineers spend years prototyping a new accessory, the placement of its buttons, the location of the electronics, the materials, its environmental footprint and its cost, then make many, many prototypes, first in foam, then 3D printing. For a vertical mouse, the brand will imagine several different sizes and have them tested blindly, in order to collect first impressions. Nothing is really left to chance.

Giant antennas and expensive machines: a mouse's journey

Technologically speaking, how a mouse works is not rocket science. A laser measures movement on a surface and communicates the information with a computer via Bluetooth. It's not for nothing that so many brands are manufacturing their own mice in 2024, sometimes at very low prices.

However, at Logitech, manufacturing a mouse is a matter of scientific mastery. The engineers we met have one thing in common: having spent several decades studying a single aspect of the product, to become the greatest experts on the planet. In the “tracking room” for example, François Morier is a specialist in lasers. His team designed the first prototypes of sensors capable of operating on glass, then miniaturized them to integrate them into mice. His lab tests the device on light, light reflective, dark receptive, and dark diffusing surfaces, at different speeds, to train them to never make a mistake.

Advertisement

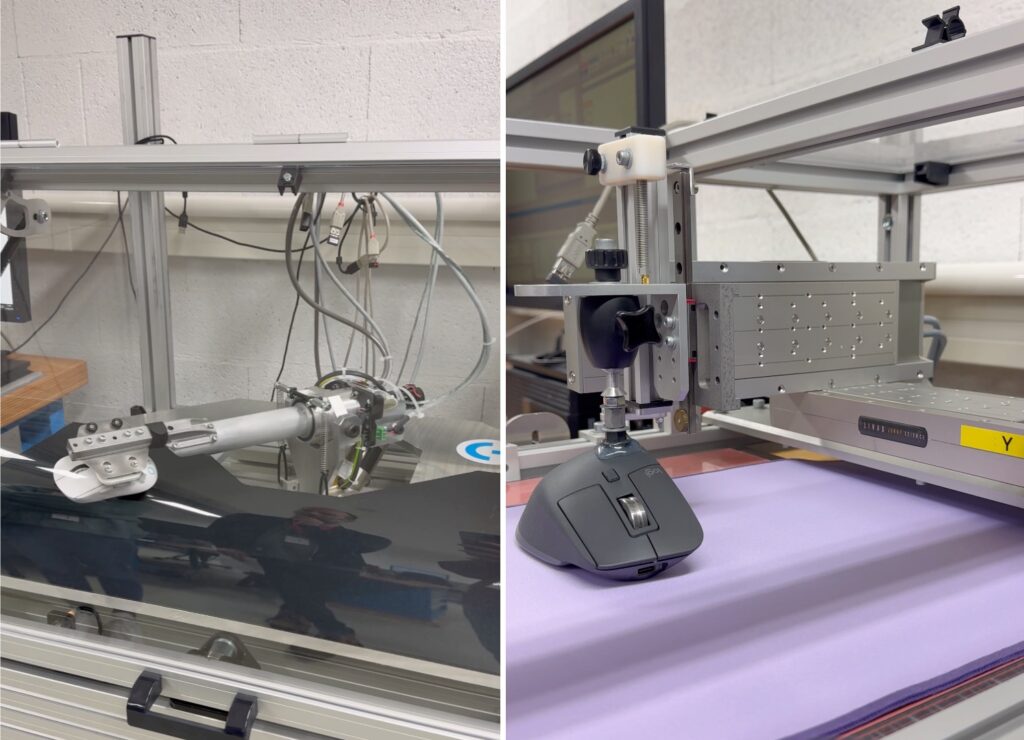

Logitech manufactures the lenses for its mice and designs its own testing machines, which involve sticking mice to a robotic arm that will shake them in all directions. A computer collects travel data.

In another laboratory, Logitech hides anechoic chambers. The brand is not afraid to compare them to those of Apple or other tech giants, since it says it thinks that brands with such a level of hardware are quite rare. There, engineers specializing in waves carry out astonishing tests. A machine can reproduce Bluetooth/Wi-Fi waves from a café, an open space or a living room, to create interference. If a mouse does not pass all the tests, Logitech reviews its design, so that the user is never disconnected.

In the same laboratory, several giant antennas, whose total budget easily exceeds 500,000 euros, analyze wave emissions from keyboards and mice. Logitech thus ensures that it validates the standards, while verifying that its product does not consume too much. The autonomy of a mouse or keyboard depends on its ability not to dissipate too much energy.

Sensors on the arm to analyze back posture

Finally, Logitech has another rather unique laboratory: the Ergo Lab. Dr. Agnès Masson, a specialist in the physiognomic impact of products on the human body, is its scientific manager.

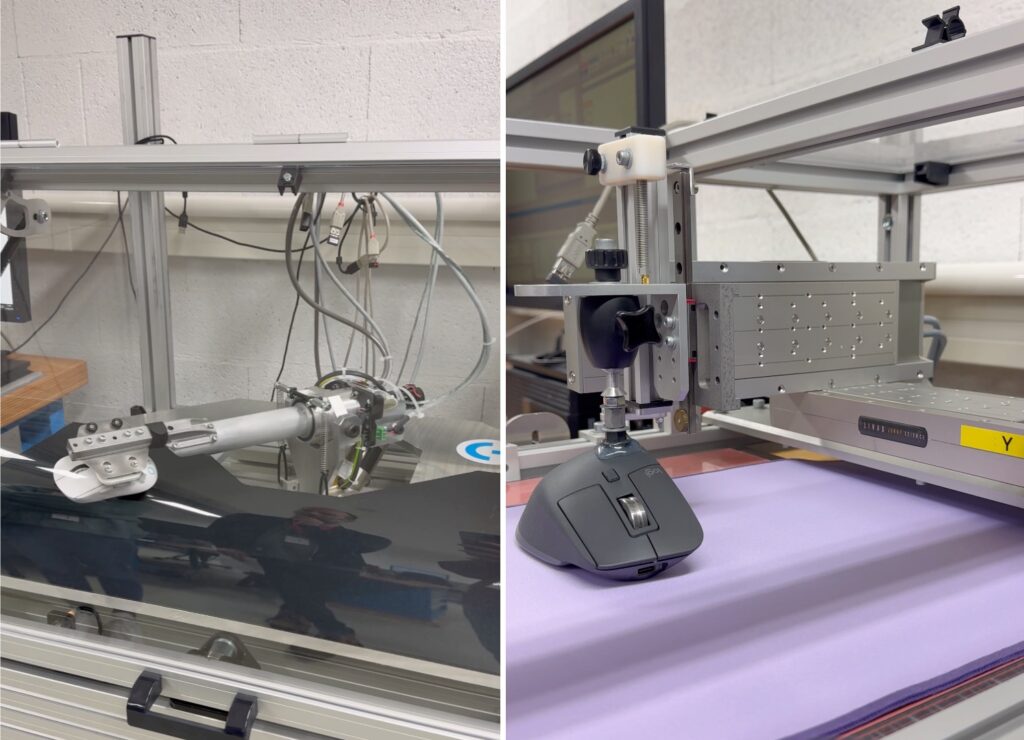

At the Ergo Lab, Logitech uses sensors to test the impact of its products on the human body. Being hunched over your computer deforms the neck, since it does not always support the weight of the human head. For each new product, Logitech ensures that the proposed shape does not pull on the bones, at the risk of causing pain in the medium term.

The idea is to analyze the muscle of the thumb, fingers (in the event of a click) and the positioning of the arms with an electrical signal.

The first observation is obvious: a horizontal mouse, the smaller it is, crosses the bones of the forearm. Conversely, a vertical mouse, which Logitech sells as an “ergonomic mouse,” allows the bones to remain separate. A left-handed person will also prefer a mouse designed for the shape of their hand, so as not to twist in all directions.

For each new product, Logitech carries out this test with around twenty guinea pigs, to observe the differences depending on the sizes and habits of each person. To his knowledge, no other brand has copied it in this aspect. The same tests are carried out for keyboards.

In short, there is a difference between a mouse made by an accessories specialist and an ordinary brand, which will only think about the appearance of the product to sell it. Designing a mouse, more than 40 years after its invention, remains a delicate exercise. For our part, we survived the electricity in our arms.